[VIPfirst7year] index:6

[VIPfirst7year] index:6 Mobiltelefon:15820024887

Email:2850991637@qq.com

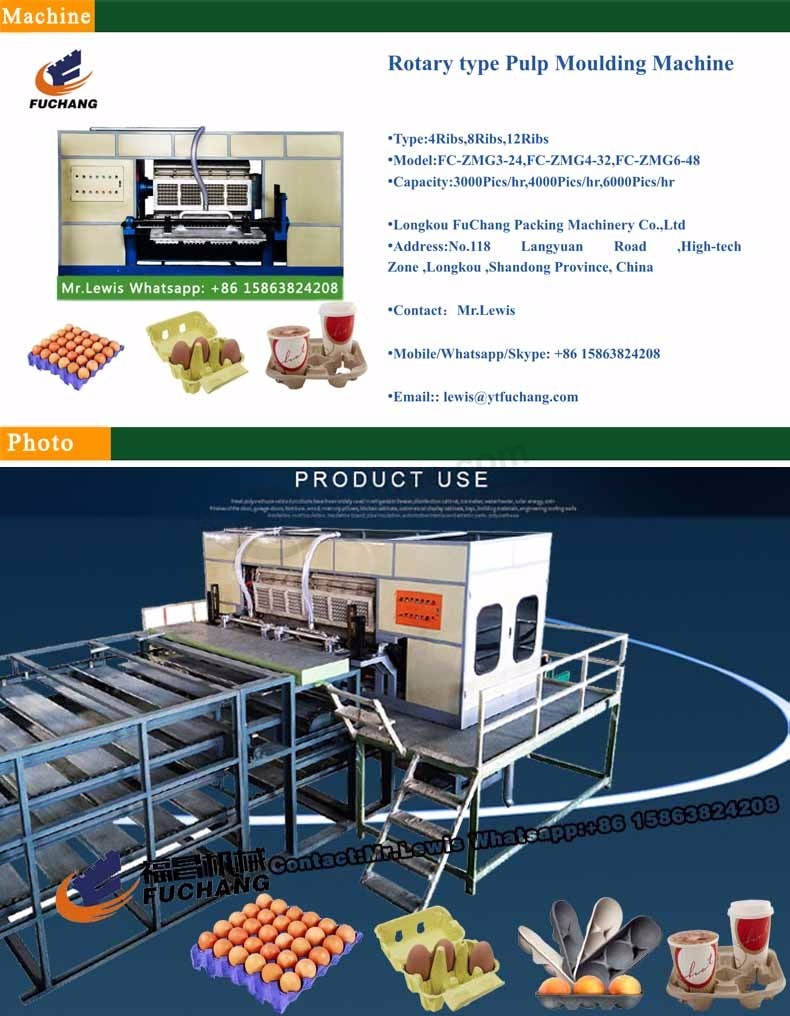

New Egg Box /egg tray making machine /fully automatic paper plate making machine

- condition:

- New

- product Type:

- Egg tray machine

- processing Type:

- pulp molding machine

- place of Origin:

- china

- brand Name:

- fuchang

- voltage:

- 380

- power(W):

- 150

- dimension(L*W*H):

- 25M*2.3M*3.9M

- weight:

- 40

- certification:

- CE, CE iso9001

- production Capacity:

- 750-6000pic/hr

- after-sales service Provided:

- engineers available to service machinery overseas, online support

- materail of mold:

- 6061aluminum alloy

- process of mold:

- CNC

- mould life:

- 6-10years

- design software:

- CAD

- application:

- paper Egg Tray,Egg carton

- cavity of paper egg tray:

- 30

- size of paper egg tray:

- 15lbs,15.5lbs,16lbs,17lbs,20lbs

- surface treatment:

- mirror surface

- warranty:

- 1year

packaging & delivery

- selling Units:

- single item

- single volume:

- 240 cm 3

- single gross weight:

- 400000.000 kg

- package Type:

- standard export packing

- picture Example:

- lead time :

quantity(Sets) 1 - 1 2 - 2 3 - 10 >10 Est. Time(days) 60 70 90 To be negotiated

online customization

New Egg Box /egg tray Making machine /fully automatic Paper plate Making machine

pulp moulding production line bring in advanced technology to develop and exploit our own FC brand products. It gets good comments from customer and gain social acceptance in society as a result of its excellent performance characteristic. The main part of our rotary Type Egg tray Machine use stainless steel material ,other auxiliary parts of Egg tray Machine adopt domestic famous brand. We already develop automatic counting stacking and packing system etc.FC series Drum type Egg tray machine features of high efficiency, low maintenance and energy saving .The pulp molding system can use all kinds of waste paper to produce high quality molded fiber products .With different moulds it can produce egg trays, vegetable trays, fruit trays, can trays, seedling tray, etc.

pulp moulding Machinery is the machine which can use all kinds of waste paper as the raw material to produce egg tray, egg box, pizza box, industrial tray and other packing products etc. by changing different moulds. It has received good reputation for its good quality, high output, low energy-consuming and low maintenance.

The raw material use general waste paper, like old book, newspaper.carton books ,etc

principle of fully automatic paper plate making machine:

after take sanitary measures of the waste paper, put the waste paper into hydrapulper with water. after progress of batting pulp , grind pulp, size mixing, then send the pulp into molding machine by pump. The foaming mould continuously uniform rotation, the mould absorb the pulp by vacuum, the pulp which adsorb to the mould uniformly dehydrate by filter and dehydration hole, guarantee product and the mould compatibility. when the foaming moulds matched with transfer moulds ,the automatic control system send compression air to control the forming molds, at the same time, transfer mold form a vacuum, the product is send to the transfer mould , then the transfer mold put the product on to the conveyer belt of drying line. The Egg tray Machine line also equipped with automatic packing ,automatic stacking and counting system so the products can packing well.

The whole paper egg tray making machinery including pulp making system + egg tray molding system + egg tray drying system + egg tray packing system.

(1):Pulping system of fully automatic paper plate making machine:

paper pulp making is the first step of the pulp mold products .The major equipment are:Hydraulic pulper ,pulp pump,water pup,stirrer,screen machine(vibration sieve,refiner machine and control cabinet. hydraulic pulper and refiner machine are two major equipment in this system.

(2):Forming system of fully automatic paper plate making machine:

this part mainly is the egg tray forming machine. We could produce the forming mould and transfering mould based on our customers request. The material of the mould could be Alumminum, Resin, Plastic. And we can produce 4face,8face,12face rotory Egg tray Machine.

generally speaking the pressure indication of the vacuum should between 0.03-0.04,The gas tank should between 0.6-0.8 .when both of them satisfy the requirement at the same time .the product will have high effect and stable quality.

(3):Drying line of fully automatic paper plate making machine:

The drying of the product is very important ,it is directly related to the humidity of the products. The whole system is droved by the conveyor. The drying line including front transmission, rear drive, driver, air blower ,bellows ,damp-proof machine ,valves and burners

adopt tunnel type drying line, chain drive smoothly and installs single burners. using single wind mouth drying, heated evenly, product little deformation, stable quality. moisture recycled second use, environmental protection and energy saving. Multi-layer drying line can save floor space

So We can supply Single layer or multi layer dryer for our client.If your factory is not long enough,You can chose our multi layer dryer.

(4):Packing machine of fully automatic paper plate making machine:

this is the last step of Egg tray Machine, when we get the finished tray from the drying line, we can packing the egg tray.

automatic stacking and counting machine: collect the egg trays and put them in order automatically, counting with induction.

operating flow of fully automatic paper plate making machine:

1.Preparation: Put the waste paper and water into hydraupulper, when it forming pulp, put the pulp into first pulp pool, then the pulp through refiner to the second pulp pool. pulp Concentration: water/waste paper 1000kg / 10kg

2.Open the air compressor, connect the reciprocating machine’s power supply, then open the touch screen and into the operation interface. In manual mode, press transferring molds enter, transferring molds will be innermost of the reciprocating machine, press the forming molds rise, forming molds and transferring molds overlap.

3.Open pulp pump, when the pulp up to the overflow pulp slot position, then open the vacuum pump, open the water valve of the vacuum pump.

4.When the product good and stable, make the manual-automatic switch of touch screen slide to automatic operation, the machine to run automatically.

5.If need stop machine or the machine goes wrong, please immediately close the emergency Stop switch or make the manual-automatic switch slide to manual operation.

The main technical Parameters of our pulp moulding machine | |||

model: | FC-ZMG3-24 | FC-ZMG4-32 | FC-ZMG6-48 |

output pcs/h: | 2800-3200 | 3800-4200 | 5000-6000 |

molding Mould/pcs: | 24 | 32 | 48 |

transfer Mould/pcs: | 3 | 4 | 6 |

contact: | Mr. lewis |

email: | lewis#ytfuchang.com (#=@) |

skype: | lewis15863824208 |

QQ: | 15863824208 |

wechat: | lewis15863824208 |

whatsapp: | +86 15863824208 |

website: | www.ytfuchang.com |

The nearest airport is yantai airport,We will pick you up at yantai airport when you come to visit us | |

outside Package:

export standard packing.

inner Package:

EPE stretch film with Wooden pacakge for long time ocean shipping.

We will service for you and solve all the problem for you by 7*24hours:

1.We will arrange our professinal engineer go to your country to install and test the machine and train your engineers.

2.Our salesman will be 7*24 hours online for you to solve any problems from your side.

3.We have been in this line for business for more than 20years.So we have abuundant experience of producing machine.

4.Our machine is hight quality.We are your trustable manufacturer of machine

5.contact with us.We can provide you non-stop service with the pre-sale,sale and after sale service. save your purchasing cost and maintenance costs

Q1:How many countries have your machine been installed ?

A2:Our machines have exported to many countries such as:

korea,Japan,Kazakhstan,Uzbekistan,Malaysia,Russia,Poland,France,Turkey,Thailand,Vietnam,Brazil,Columbia,Argentina,Costa Rica,Algeria,Nigeria,Malawi,Bolivia,Sudan,Jordan,Egypt,South Africa,etc.

Q2:How about the visiting

A2: We are located in longkou City,Shandong Province,China.

The nearest airport is yantai Airport.You can transfer from guangzhou ,Beijing or shanghai airport to yantai Airport.

We will pick you at the yantai airport when you come to visit us.

Q3:Will you test machine before placing order?

A3:We will make the machine running during your visiting to check the working condition.

And there are some client who bought our machine in our city,We will take you to their factory to check all working flow.

Q4:Will you conduct training for our staff here?

A4:Yes,We will arrange our professional engineers to install and test machine and train the buyer’s engineers.

Q5:What are your terms of payment?

A5:We accept T/T, L/C.Western union and Cash.

-

Hh-C1 Siebdrucktisch(Flach)Mit OEM Service

Hh-C1 Siebdrucktisch(Flach)Mit OEM Service

-

Hh-A1 ovale automatische Siebdruckmaschine

Hh-A1 ovale automatische Siebdruckmaschine

-

Hh-M1 trocknender Trockner (allgemein) Porzellanfabrik

Hh-M1 trocknender Trockner (allgemein) Porzellanfabrik

-

Hh-M2 Tunneltrockner(Energieeinsparung)China Hersteller

Hh-M2 Tunneltrockner(Energieeinsparung)China Hersteller

-

Hh-L2 UV-Härtemaschine (mit Trocknung) zu verkaufen

Hh-L2 UV-Härtemaschine (mit Trocknung) zu verkaufen

-

Hh-A3 doppelt-Radsiebdruckmaschine

Hh-A3 doppelt-Radsiebdruckmaschine

-

Hh-G2 orientierter Siebdrucktrockner zum Verkauf

Hh-G2 orientierter Siebdrucktrockner zum Verkauf

-

Hh-P1 hochwertige vertikale beater fabrik china

Hh-P1 hochwertige vertikale beater fabrik china

Chatte jetzt!

Chatte jetzt!